Rootstock Cloud ERP System for Aerospace & Defense Manufacturers

Every tail number—and therefore, every sub-component—requires rigorous documentation for lot number and serial number. Disparate systems for sales, supply chain management, and production operations make documentation challenging without robust visibility across the supply chain. Rootstock’s Cloud ERP software for Aerospace & Defense manufacturers is an end-to-end ERP system designed to accurately manage all metadata from cradle to grave and support rapid business growth.

The Power of Real-Time ERP Reporting & Data Visibility

“Rootstock’s Cloud ERP was exactly what we wanted – modern and dynamic. It met our requirements and was a one-stop shop, capable of handling production, purchasing, and finance – all from one cloud rather than multiple platforms.”

Watch a Demo of Rootstock Aerospace ERP Software

Why the Salesforce Platform is Great for Aerospace ERP

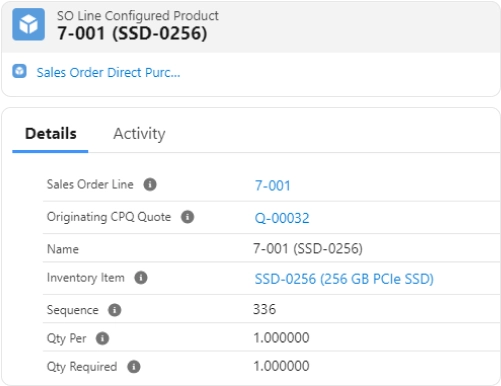

When you run ERP on the Salesforce Platform, you put your customers at the heart of your business, shift the focus of IT onto strategic projects, and reduce costs while gaining a 360° view of your customers and your business.

By integrating a modern Cloud ERP system with Salesforce, aerospace and defense manufacturers remove the business silos that divide CRM and ERP data to create a single, shared view of all customer interactions and your entire business.

“We selected Rootstock on its own merit as we knew it was agile and supported our aerospace business. After further analysis, we saw the benefit of the Salesforce platform, which gave us more opportunities in the future.”

Complete Project Lifecycle Management

Complete Project Lifecycle Management Full Traceability for Regulatory Compliance

Full Traceability for Regulatory Compliance Cost Controls

Cost Controls