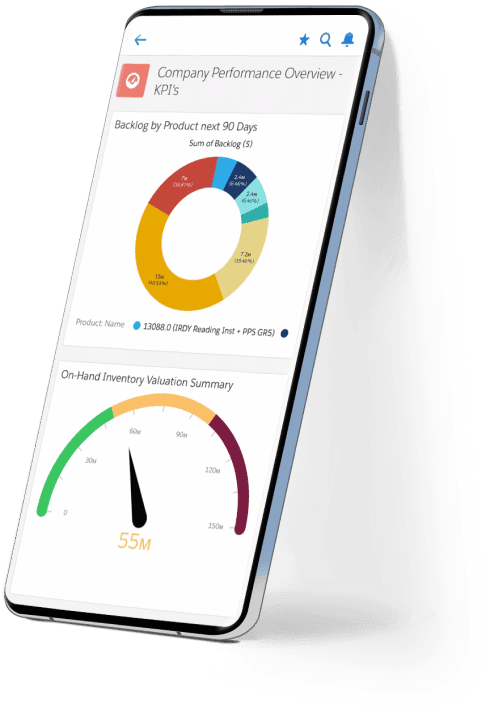

Rootstock ERP for Electronics Manufacturing Provides 360° Visibility into Operations

Rootstock’s electronics manufacturing ERP software provides complete visibility, control, and traceability, helping manufacturers manage changing demand, short product lifecycles, and evolving regulatory requirements.

Boston Dynamics Achieves Fundamental Business Transformations

“One reason we selected Rootstock is that the ERP can handle complex manufacturing.”

“I was blown away by the integration of the solution using the same singular data set, the same objects, the same security model, the same authorizations. That was tremendous to me.”

Watch a Demo of Rootstock's ERP for Electronics

Take 4 minutes to see how Rootstock’s Cloud ERP software for Electronics & High-Tech manufacturers is designed to accelerate business growth and manage manufacturing operations with ease.

Efficiently Manage High-Volume Production

Efficiently Manage High-Volume Production Full Traceability for Regulatory Compliance

Full Traceability for Regulatory Compliance Integral Service & Support

Integral Service & Support