Manufacturing Inventory Software

Precisely manage inventory and costs in real-time and across multiple locations all from any device with Rootstock Manufacturing Inventory Software.

Rootstock Inventory in under 60 Seconds

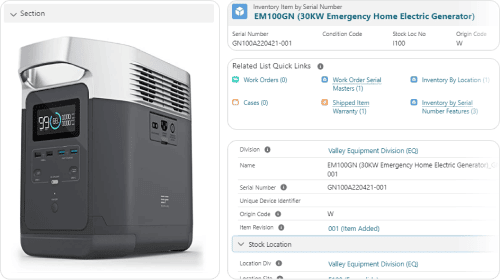

Quickly Gain Detailed Lot Control and Serial Number Tracking

- Register lot numbers through purchase receipts, inventory, shop floor control, and sales orders.

- Assign serial numbers to inventories and track it all the way to sales order fulfillment.

- View full-level traceability trees and comprehensive device history records with lot control and serialized inventory.

Easily Classify Manufacturing Inventory and Assign Item Attributes

- Pre-assign inventory types or assign them on the fly using detailed classifications to quickly identify and locate specific items.

- Maintain common or project inventories by item and at a division, site, or location level.

- Track costs and quantities at the item level and use license plating to manage containerized inventories.

Accurately Track Inventory and Manage Costs

- Use soft allocation counts to plan material needs, control projects, and reserve inventory for specific orders or production lines.

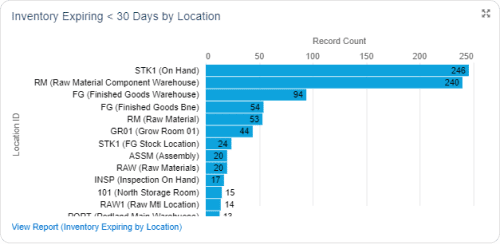

- Create customized cycle counting parameters, count and categorize inventory using ABC analysis, and easily distribute inventory reports.

- Improve collaboration with customers and partners by managing consigned inventory based on customizable locations.

Why Rootstock Manufacturing Inventory Control Software?

“Rootstock provides the functionality we never had before, which is a dynamic, detailed look at inventory, cost of sales, and sales. It gives us a real-time ability to dissect pretty much anything we want. It’s a big benefit.”

“We had no visibility to see how demand was interconnected at a part level. Rootstock helped us connect the sources of demand and increase our production efficiency.”

Schedule a Personalized Demo for Your Team

Benefits of Rootstock Manufacturing Inventory Software

Our cloud-based ERP and manufacturing inventory management system gives you the insights to minimize inventory costs, keep production running smoothly, and ensure customer orders are fulfilled on time. With purpose-built inventory management software designed by and for manufacturers, you can make better decisions faster and with fewer errors.

- Real-Time Inventory Management: Analyze supply and demand changes as they happen and quickly update inventory by location, lot, serial number, or project.

- Dependable Inventory Accuracy: Gain more control with detailed transaction histories, customizable cycle counts, and ABC category analysis while managing costs with standard, actual, or FIFO costing.

- Reduce Inventory Investments: Accurately track all materials to make informed decisions, increase inventory turns, and proactively manage costs at every level.

- Traceability from Supplier to Customer: Classify and track material as it moves across locations and automatically register receipts and assign serial numbers as inventory makes its way to customers.