Rootstock Discrete Manufacturing ERP Software

Managing demand against supply and consistently delivering on time is key to satisfying—or ideally, delighting—your customer. Rootstock’s discrete manufacturing software delivers an end-to-end ERP system purpose-built for discrete manufacturers with the flexibility to match your needs today and the scalability to grow with you as your needs grow. With Rootstock, discrete manufacturers enjoy a single source of truth across their digital thread to create a single, shared view of all customer interactions across your entire business.

``Rootstock has a lot of experience in manufacturing and the potential to adapt and work with our processes as a smaller company looking at growth and expansion.``

``We're able to use real time material pricing connected to our estimating solutions and deliver better pricing to our customers, but also deliver better results on our projects.``

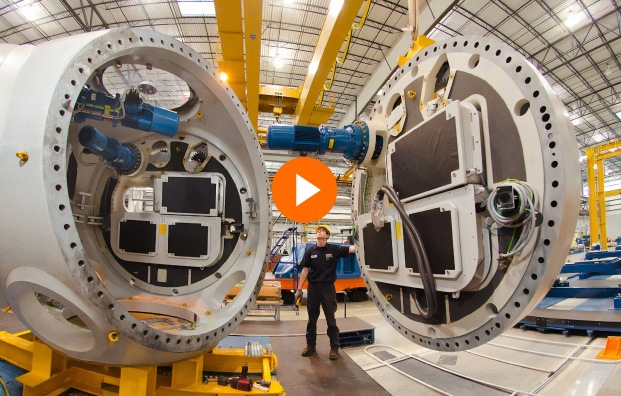

Watch a 4-minute Demo of Rootstock Discrete Manufacturing ERP Software

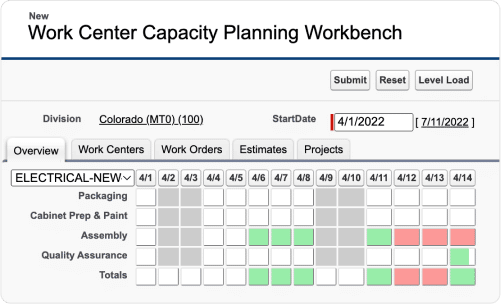

Complete Visibility from Demand to Supply

Complete Visibility from Demand to Supply Support for Multiple Manufacturing Modes

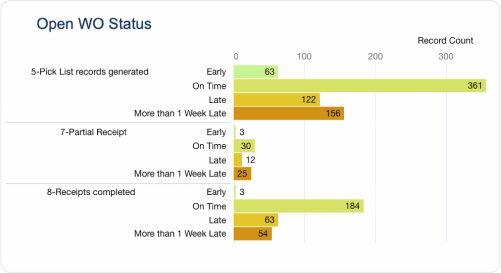

Support for Multiple Manufacturing Modes End-to-End Production Control

End-to-End Production Control