Manufacturing Production Software for Planning Excellence

Rootstock Manufacturing Production Scheduling Software automates your entire production process with enhanced scheduling visibility, end-to-end shop floor control, and drag-and-drop capacity planning.

See How Rootstock ERP Improves Production Planning & Scheduling

Production Planning and Scheduling for Increased Efficiency

- Gain Deep Visibility into Plans and Schedules: Visualize capacity to address production bottlenecks, eliminate over- or under-production, and connect materials availability with scheduled work orders.

- Shorten Production Cycle Times: Control and mix production modes across orders, track and manage work orders from planning to shipping, and dynamically adjust and route production in real-time.

- Easily Achieve Higher Quality and Compliance: Deliver on quality and compliance requirements with complete traceability, comprehensive inspection audit trails and histories, and less waste and rework.

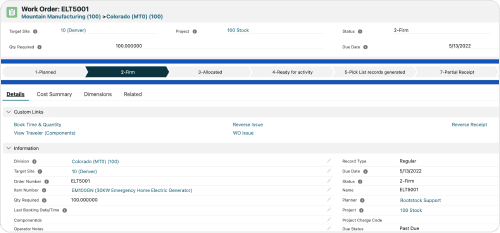

Streamline Work Orders in a Single ERP System

- Manage the End-to-End Work Order Lifecycle: Track each work order from start to finish, dynamically adjust BOMs and routings in real-time, and connect custom work orders to sales opportunities.

- Create Efficiencies in Work Order Processes: Easily fulfill work orders with control at every level, including release, picking material, booking, quantity recording, receipt, backflushing, and costing.

- Manage Work Orders with Drag-and-Drop Ease: Create tear-down work orders, salvage finished parts or subassemblies, level load demand across work centers, and check material availability before scheduling work orders.

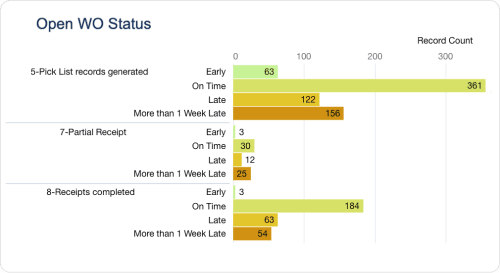

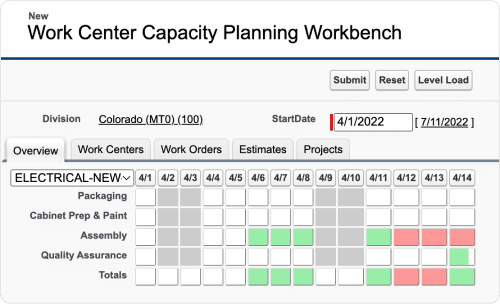

Identify and Fix Shortages and Overloads with Scheduling & Capacity Planning

- Easily Visualize Capacity at a Glance: Manage work center capacity by labor or machine hours on one intuitive interface.

- Gain 360°/365 Shop Floor Control: Track orders, materials, and components throughout production, capture hours and materials to account for costs, and enable alternate routings.

- Track Detailed Metrics to Reduce Downtime: Gain a bird’s-eye view of equipment repair schedules for coordinated planning and reduced downtime.

“One reason we selected Rootstock is that the ERP can really handle complex manufacturing.”

Streamline ERP Production and Materials Flow

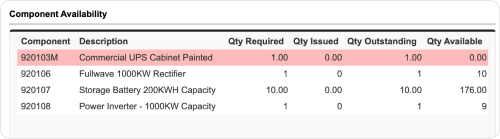

- Manage Complex BOMs: Dynamically adjust BOMs or routings to respond to real-time production conditions and explode BOMs to see assemblies broken down to individual components and parts.

- Improve Production Efficiency: Use work orders and scheduling together to see when parts are available and purchased items are required.

- Mix Production Modes and Cater to Every Customer Need: Easily manage make to order, make to stock, engineer to order, and other manufacturing modes, and even mix different modes across facilities.

Schedule a Personalized Production Planning Software Demo for Your Team

Why Choose Rootstock Manufacturing Production Software

When combined with Salesforce Manufacturing Cloud, Rootstock Cloud ERP offers manufacturers, distributors, and supply chain businesses a single platform on which to grow and manage your operations. Rootstock Production ERP System lets you control and automate your production process, reduce the risk of human error, increase productivity, and reduce downtime. With a production planning and scheduling software such as this, you can:

- Gain a Competitive Edge with a Flexible, Customizable Production ERP: Easily deploy an ERP application tailored for your company, working precisely for your unique needs, using intuitive, low-code technology.

- Improve Collaboration Internally and With Customers and Suppliers: Stay in close contact with key stakeholders using features like embedded social media and custom portals, and stay in the loop from any mobile device, anywhere in the world.

- Better Guide Production with Advanced Analytics & Reporting: Use advanced analytics and artificial intelligence to spot patterns and trends, make better decisions, and stay ahead of shifting trends.

- Control Quality and Maintain Compliance: Seamlessly integrate with ComplianceQuest EQMS and other compliance apps on the Salesforce Platform to exceed customers’ quality expectations and stay compliant with rules and regulations.