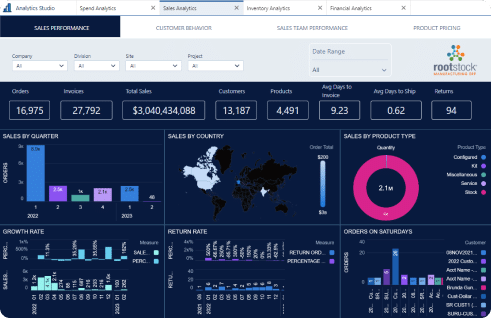

Rootstock Manufacturing ERP System Overview

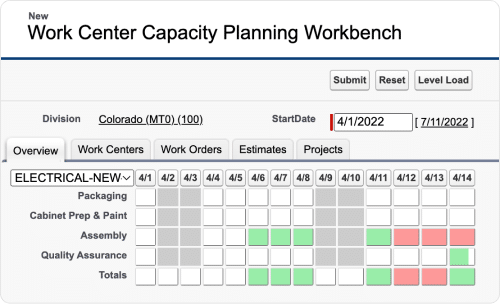

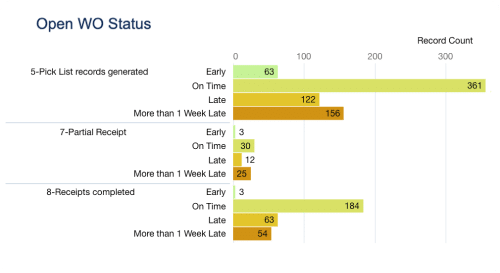

One connected manufacturing ERP software platform and partner ecosystem to support your entire manufacturing operations. Effectively manage sales signals to predict production capacity while making decisions faster with a 360° view – accessible from anywhere, on any connected device. Partner with Rootstock to accelerate your business success today.