Bill of Materials Software to Improve BOM Management

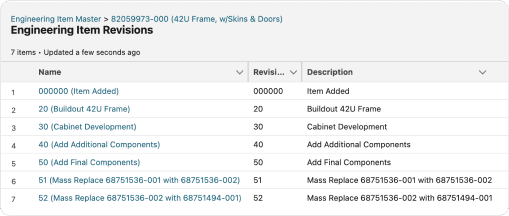

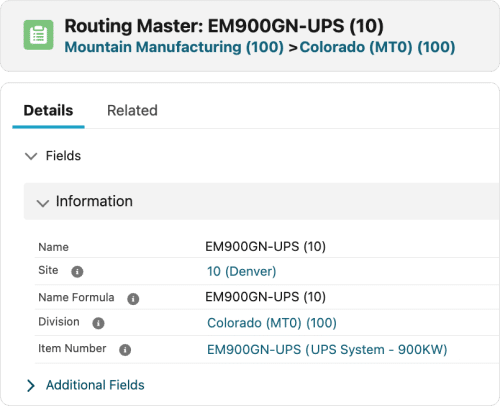

Rootstock BOM software helps improve the BOM management process for manufacturing organizations by providing enhanced revision and engineering change management control, better product costing controls, and the ability to create flexible routings.

See how Rootstock Cloud ERP improves the BOM management process

Cross-Departmental Bill of Materials Software

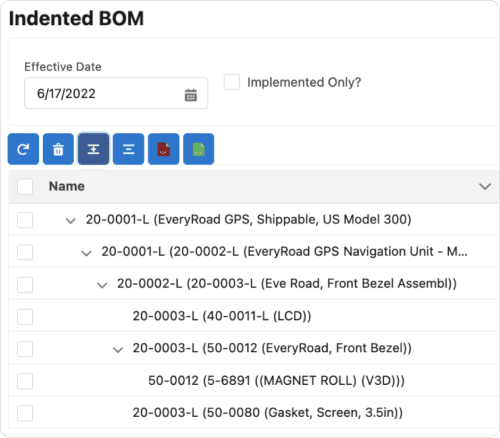

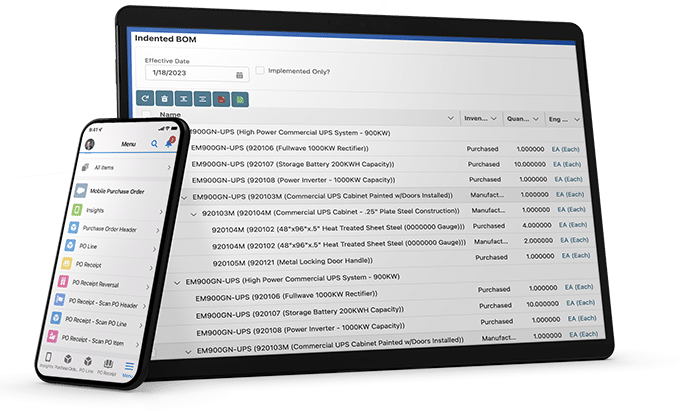

You may produce multiple products but when you have multiple versions or configurations of those products, keeping BOMs synced up with orders is challenging. Rootstock Bill of Materials software capabilities support different needs of engineering (eBOMs), manufacturing (mBOMs), and service (sBOMs) in working together on products to reduce confusion and resulting errors.

Schedule a Personalized Demo for Your Team

“BOM Maintenance is a beautiful thing, we can copy, clone, and maintain our BOMs much more efficiently than we could before.”

See how Rootstock BOM Software Improves BOM Management